Types of Fixtures

Types Of Fixtures:

Milling Fixtures:

A Milling fixture is a work holding device which is firmly clamped to the table of the milling machine. It holds the work piece in correct position as the table movement carries it past the cutter or cutters.

Essentials of Milling Fixtures:

1: Base:

A heavy base is the most important element of a milling fixture. It is a plate with a flat and smooth under face. The complete fixture is built up from this plate. Keys are provided on the under face of the plate which are used for easy and accurate aligning of the fixture on the milling machine table. By inserting them into one the T slot in the table. These keys are usually set in keyways on the under face of the plate and are held in place by a socket head cap screw for end key. The fixture is fastened to the machine table with the help of two T bolts engaging in T slots of the work table.

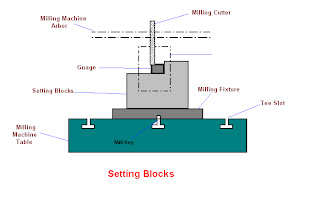

2: Setting Blocks:

After the fixture has been securely clamped to the machine table , the work piece which is correctly located in the fixture , has to be set in correct relationship to the cutters. This is achieved by the use of setting blocks and feeler gauges. The setting blocks is fixed to the fixture. Feeler gauges are placed between the cutter and refrence planes on the setting block so that the correct depth of the cut and correct lateral setting is obtained. The block is made of hardened steel and with the refrence planes(feeler surfaces) grooved. In it correct setting , the cutter should clear the feeler surfaces by at least 0.08cm to avoid any damage to the block when the machine table is moved back to unload the fixture. The thickness of the feeler gauge to be used should be stamped on the fixture base near the setting block.

3: Locating and Clamping Elements:

The same design principles of location and clamping apply for milling fixtures have been discussed above.

Some Design Principles for Milling Fixtures:

1: Pressure of cut should always be against the solid part of the fixture(fig a).

2: Clamps should always operates from the front of the fixture (fig B)

3: The work piece should be supported as near the tool thrust as possible(fig c)

10:44 PM

10:44 PM

, Posted in

, Posted in